cure time for polyurea floors

Epoxy vs. Polyurea Floors: Which surface is Right for You?

Have you wondered if there are options to epoxy as a surface finish and if it’s the best option? When it comes to choosing the right surface for your flooring needs, epoxy and polyurea floors are two popular options to consider. Both offer a range of benefits and considerations that can impact your decision.

In this article, we will compare epoxy and polyurea floors in terms of durability, cost, aesthetics, maintenance, installation, and environmental considerations. By exploring the differences between these two surfaces, you’ll be equipped with the knowledge to make an informed decision that suits your specific requirements.

Introduction

Choosing the right flooring surface for your needs is crucial. Whether you are renovating your home, office, or industrial space, selecting the right type of floor can significantly impact its functionality and aesthetics. In this article, we will compare epoxy and polyurea floors, two popular options for durable and visually appealing surfaces. By examining factors such as durability, cost, aesthetics, maintenance, installation, and environmental considerations, we will help you make an informed decision about which flooring solution is best for you.

Both products are known for their durability and versatility. However, they have distinct characteristics that make them suitable for different applications. Understanding these differences will enable you to choose the flooring surface that aligns with your specific requirements and preferences.

Understanding Epoxy Floors

What is epoxy?

Epoxy floors are a type of concrete coating that is created using epoxy resin, a durable and versatile polymer. Epoxy resin is mixed with a hardening agent to create a chemical reaction that results in a strong, rigid material. This material is applied in its liquid state as a coating to concrete surfaces, forming a protective layer that enhances durability and aesthetics.

Epoxy floors are known for their exceptional durability, making them ideal for high-traffic areas such as commercial spaces, warehouses, and garages. The polymer composition of epoxy floors provides excellent resistance to impact, abrasion, and heavy loads, ensuring that they can withstand the rigors of daily use without deteriorating.

The durability and resistance to chemical penetration as well as the ease of maintaining in a clean and sterile condition are just some of the attractions to this surface. When you add the appearance factor they are a very attractive choice for commercial, medical and residential floor surfaces.

Understanding Polyurea Floors

In the world of flooring options, polyurea floors have gained significant attention for their exceptional characteristics. Let’s dive into what makes polyurea such a remarkable choice for a durable, flexible, and highly resistant surface.

What is polyurea?

Polyurea is a synthetic polymer that belongs to the family of elastomers. It is created through a reaction between an isocyanate and a resin blend, resulting in a flexible and highly durable material. Polyurea is commonly used as a coating for various surfaces, including floors, due to its exceptional performance and longevity.

Polyurea floors are renowned for their outstanding durability. They are incredibly resistant to wear and tear, making them ideal for high-traffic areas. The flexibility of polyurea allows it to withstand impact and prevent cracking, ensuring a long-lasting and reliable flooring solution.

One of the notable advantages of polyurea floors is their heat resistance. They can withstand high temperatures without melting or deteriorating, making them suitable for industries with extreme heat conditions. Additionally, polyurea is highly resistant to chemicals, protecting the floor from potential damage caused by spills or exposure to corrosive substances.

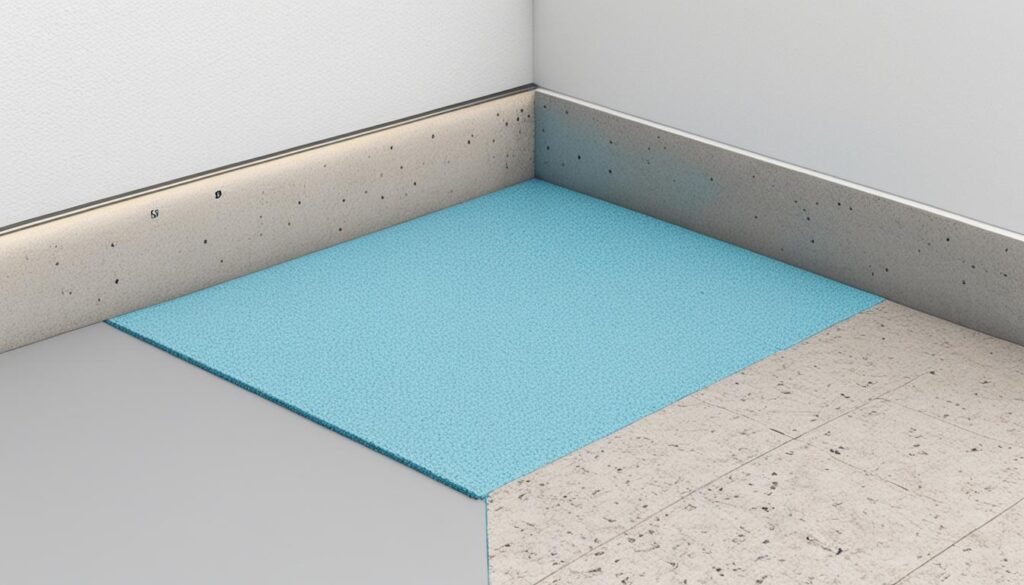

Image:

| Characteristics | Polyurea Floors |

|---|---|

| Durability | Highly durable and resistant to wear and tear |

| Flexibility | Can withstand impact and prevent cracking |

| Heat Resistance | Can withstand high temperatures without melting or deteriorating |

| Chemical Resistance | Highly resistant to chemicals and corrosive substances |

Durability and Performance

When it comes to choosing the right flooring surface, durability and performance are key factors to consider. In this section, we will compare the durability and performance of epoxy and polyurea floors, highlighting their strengths and weaknesses in various conditions and use cases.

Epoxy floors are known for their exceptional durability. They are highly resistant to impacts, making them ideal for high-traffic areas such as warehouses, garages, and manufacturing facilities. Epoxy floors also have excellent temperature resistance, able to withstand both extreme heat and cold. They are highly resistant to wear and tear, maintaining their appearance and functionality even in demanding environments. With proper installation and maintenance, epoxy floors can have a long lifespan, providing lasting durability.

Polyurea floors, on the other hand, offer unmatched impact resistance. They are highly elastic and able to absorb and disperse impact forces, making them ideal for areas prone to heavy machinery or equipment. Polyurea floors also have excellent temperature resistance, withstanding extreme heat and cold without cracking or warping. Additionally, their resistance to wear and tear ensures long-term performance and durability.

Impact Resistance:

Epoxy floors: Excellent

Polyurea floors: Outstanding

Temperature Resistance:

Epoxy floors: Excellent

Polyurea floors: Excellent

Wear and Tear:

Epoxy floors: High resistance

Polyurea floors: High resistance

Longevity:

Epoxy floors: Long lifespan with proper maintenance

Polyurea floors: Long-lasting performance

Both epoxy and polyurea floors have impressive durability and performance characteristics, but the choice ultimately depends on the specific requirements of your project. Consider the type of impact and temperature challenges your floor will face, as well as the level of wear and tear it will be exposed to. By understanding the differences between epoxy and polyurea floors, you can make an informed decision that ensures optimal durability and performance for your space.

Let me give you the 2 most obvious differences between the two products:

Strength and rigidity: Epoxy will be stronger upto 7,000PSI and completely rigid. Polyurea will be quite strong as well upto 6,000PSI but it will be more flexible and resistant to cracking with a slight movement of the substrate. How does this difference matter to you? Epoxy in an interior setting will handle stress at the surface slightly better espesially in an industrial setting of intense surface tension. Polyurea will handle heavy use but under industrial strains will wear faster. Polyureas big factor is flexibility so if applied on thinner cancrete pads or in areas with freeze thaw impacts it will perform better not being as prone to splitting or cracking.

UV Tolerence: This is probably the biggest factor to lean towards Polyurea. Its UV protection from fading or discoloration is far better than epoxy. If you are in an area that has high sun exposure or an exterior area you will be far happier with a Polyurea finished surface.

Aesthetics and Maintenance

When it comes to choosing the right flooring for your space, aesthetics and maintenance are important factors to consider. Both epoxy and polyurea floors offer a range of customization options, allowing you to create a surface that complements your design preferences. Whether you prefer a sleek and modern look or a vibrant and colorful floor, both epoxy and polyurea can be tailored to your specific aesthetic vision.

Additionally, slip resistance is a crucial aspect to consider, especially in areas prone to moisture or spills. Epoxy and polyurea floors can be formulated with additives that enhance slip resistance, providing a safer environment for you, your family, or your employees.

When it comes to maintenance, both epoxy and polyurea floors are relatively easy to clean and maintain. Regular sweeping or vacuuming, along with occasional mopping using mild cleansers, is usually sufficient to keep the floors looking their best. However, it is important to note that the specific maintenance requirements may vary depending on the type and finish of the floor.

“Customization options and slip resistance are key factors to consider when choosing between epoxy and polyurea floors. Both options offer versatility in aesthetics and can be adjusted to meet your design preferences. Additionally, their relatively low maintenance requirements make them convenient choices for various spaces.”

– Flooring Expert

Overall, the aesthetics and maintenance of epoxy and polyurea floors make them attractive options for a wide range of applications. Whether you prioritize design versatility, slip resistance, or ease of maintenance, both types of flooring offer practical and visually appealing solutions.

Installation and Costs

The installation process and associated costs differ between epoxy and polyurea floors. Both surfaces require proper surface preparation to ensure a smooth and durable finish. The application process for each type of floor also varies, as does the cure time for the coatings.

The preparation of the concrete will be the exact same to get a high quality job. The polyurea finished product is more forgiving if cracks and imprefections are not prepped properly but i would always error on the side of caution and prep them with the same attention to detail. The preparation and application process is almost identical for each of these products so the only variable that is going to be any real cost difference is in the product itself.

When it comes to installation costs, epoxy floors are generally more affordable than polyurea floors. The initial materials cost for epoxy is lower, making it a more budget-friendly option. However, it’s important to consider long-term cost considerations when making a decision. Epoxy floors may require regular maintenance and reapplication over time, which can increase the overall cost in the long run.

In contrast, polyurea floors are known for their durability and longevity, which can result in lower long-term costs. While the upfront installation cost may be higher, the reduced maintenance and long life expectancy of polyurea floors can offset these initial expenses.

| Epoxy Floors | Polyurea Floors | |

|---|---|---|

| Surface Preparation | Thorough cleaning and repair of concrete. | Thorough cleaning and repair of concrete. |

| Application Process | Mixing epoxy resin and hardener and applying it to the surface. | Roll/Squeegee polyurea onto the surface for a seamless finish. |

| Cure Time | 24 to 72 hours, depending on the product and environmental conditions. | Within hours, as polyurea has a fast-curing property. |

| Installation Costs | Lower initial cost, more budget-friendly. | Higher upfront cost, but potential long-term cost savings. |

Choosing the Right Floor for Your Needs

After considering the various aspects of epoxy and polyurea floors, it’s important to take into account your specific requirements when choosing the right floor for your needs. Here are the key factors to consider:

- Durability: Evaluate the durability of both epoxy and polyurea floors based on your intended use. Consider factors such as impact resistance, temperature resistance, and overall wear and tear.

- Aesthetics: Determine which floor offers the aesthetics you desire. Epoxy floors provide a glossy, smooth finish, while polyurea floors offer a more textured look. Consider the customization options available for each type of floor.

- Maintenance: Assess the maintenance requirements of epoxy and polyurea floors. Determine how frequently each floor needs to be cleaned and whether any specialized cleaning products or techniques are required.

- Installation: Consider the installation process for both types of floors. Evaluate the surface preparation, application process, and cure time. Determine whether you have the necessary resources and expertise for a DIY installation or if you’ll need to hire professionals.

- Costs: Compare the initial installation costs and long-term cost considerations for epoxy and polyurea floors. Factor in expenses such as materials, labor, and any potential future repairs or maintenance.

By carefully considering these factors, you can make an informed decision that aligns with your specific requirements and ensures that you choose the right floor for your needs.

| Factors | Epoxy Floors | Polyurea Floors |

|---|---|---|

| Durability | High impact resistance, temperature resistance, and wear and tear longevity | Flexible with excellent impact resistance, heat resistance, and high chemical resistance |

| Aesthetics | Glossy, smooth finish with various customization options | Textured look with limited customization options |

| Maintenance | Regular cleaning with standard cleaning products | Regular cleaning with standard cleaning products |

| Installation | Requires surface preparation, specialized equipment, and professional installation for optimal results | Requires surface preparation, specialized equipment, and professional installation for optimal results |

| Costs | Varies based on specific requirements, but generally more cost-effective | Varies based on specific requirements, but generally more expensive |

Environmental Considerations

When choosing between epoxy and polyurea floors, it’s important to consider the environmental impact of your decision. Both types of flooring have different characteristics when it comes to VOC emissions and sustainability.

Volatile Organic Compounds (VOCs) are chemicals that can vaporize and be released into the air, potentially causing health issues and contributing to air pollution. Epoxy floors typically have higher VOC emissions during the installation process, as they require the use of solvents. However, it’s worth noting that once epoxy floors cure, their VOC emissions decrease significantly. On the other hand, polyurea floors generally have lower VOC emissions, making them a more environmentally friendly option from the start.

When it comes to sustainability, both epoxy and polyurea floors have their advantages. Epoxy floors can be considered more sustainable in terms of their longevity and durability. They have a longer lifespan than many other flooring options, reducing the need for frequent replacements and thus reducing waste. Polyurea floors, on the other hand, are known for their flexibility and elasticity, making them less prone to cracking or chipping, which can also contribute to their overall sustainability.

If you prioritize eco-friendly options, you may want to explore alternative choices within both epoxy and polyurea flooring. Some manufacturers offer low VOC or VOC-free epoxy coatings, which can help minimize the environmental impact of your flooring. Additionally, there are polyurea products available that are formulated with sustainable materials or are part of recycling programs, providing more sustainable options for your flooring needs.

Brief Conclusion

As a 25 year professional in the concrete and concrete surfacing field I can tell you that the finished product in both epoxy and the Polyurea finishes is a great choice to imporove the look and durability of your concrete surface. If you are an industrial interior application you will undoubtedly prefer the impact resistance and durability of Epoxy. For an indoor decorative finish that is showroom clear or creatively styled you will enjoy the versatility of the design aspects of epoxy. For a residential or commercial application that has sun exposure or for any exterior application you will hands down want to choose a Polyurea finish.

FAQ

What are the main differences between epoxy and polyurea floors?

Epoxy and polyurea floors differ in terms of their composition, cure time, durability, and flexibility. Epoxy is a polymer that offers some UV resistance and chemical resistance, while polyurea is an elastomer known for its heat resistance, chemical resistance and is a much more realible product for UV resistance .

Are epoxy floors more durable than polyurea floors?

Both epoxy and polyurea floors offer high levels of durability. However, epoxy floors are generally more impact resistant, while polyurea floors are more flexible and have superior resistance to heat and chemicals.

What customization options are available for epoxy and polyurea floors?

Epoxy and polyurea floors can be customized to match any aesthetic preference. Epoxy floors can be colored, textured, and even incorporate decorative elements like metallic flakes or quartz crystals. Polyurea floors can also be pigmented and have options for different finishes, including glossy or matte.

How do I maintain epoxy floors?

Epoxy floors are easy to clean and maintain. They require regular sweeping or vacuuming to remove dirt and debris. Spills should be cleaned up promptly to prevent staining. Periodic mopping with a pH-neutral cleaner is recommended to keep the floor looking its best.

What is the installation process for epoxy floors?

The installation process for epoxy floors typically involves surface preparation, which may include grinding or shot blasting. The epoxy resin is then mixed with a hardener and applied to the prepared surface. It requires proper curing time to ensure a strong bond and durability.

How much do epoxy and polyurea floors cost?

The cost of epoxy and polyurea floors can vary depending on factors such as the size of the area, the condition of the substrate, and the complexity of the design. Generally, epoxy floors are more cost-effective than polyurea floors, but it’s important to consider long-term maintenance and durability when making a decision.

What factors should I consider when choosing between epoxy and polyurea floors?

When deciding between epoxy and polyurea floors, consider factors such as durability, aesthetics, maintenance requirements, installation process, and costs. Assess your specific needs and priorities to determine which type of flooring best aligns with your requirements.

How do epoxy and polyurea floors impact the environment?

Epoxy and polyurea floors can emit volatile organic compounds (VOCs) during installation. However, there are environmentally friendly options available, such as low-VOC or zero-VOC coatings. Additionally, polyurea is considered more sustainable as it has a faster cure time, reducing energy consumption during installation.

Source Links

- Stamped Colored Concrete: Transform Your Outdoor Space

- Patio Makeover: Comparing Decks, Pavers, and Concrete Options

- Epoxy vs. Polyurea Floors: Which surface is Right for You?

- Achieving Professional Results with DIY Epoxy Floor Installation

- A Comprehensive Guide: Things To Consider Before Staining Your Concrete

- Unveiling the Secrets of Penetrating Concrete Stains: A Comprehensive Guide

- Mastering Concrete Staining: Must-Have Supplies and Expert Tips

- Choosing the Best Long-Lasting Concrete Stains: A Comprehensive Guide

- DIY Interior Concrete Staining: A Step-by-Step Guide for Stunning Results

- A Complete Guide to Sealing Concrete After Staining: Tips for Protection and Enhancement

- How to Remove Unwanted Concrete Stains: A Comprehensive Guide

- Mastering the Art of Concrete Preparation for Staining: A Comprehensive Guide

- Maintaining Your Stained Concrete: Essential Tips for Longevity

- Unlock Creativity and Savings with DIY Water-Based Concrete Stain

- DIY Epoxy Concrete Floors: A Step-by-Step Guide for Stunning Results

- DIY Concrete Stains: A Comprehensive Guide for Successful Projects

- Concrete Staining: DIY or Professional? A Comprehensive Guide

- Concrete Staining vs. Epoxy Coating: A Comprehensive Guide for Choosing the Right Finish

- Concrete Staining vs. Concrete Painting: A Comprehensive Guide

- Exploring Concrete Staining: Pros, Cons, and Considerations for Your Project

- Unlocking Creative Brilliance: Concrete Staining Ideas for Stunning Surfaces

- Mastering Concrete Staining: How to Solve Common Problems and Achieve Stunning Results

- Common Concrete Staining Mistakes And How To Avoid Making Them: A Comprehensive Guide

- Unveiling the Best Places to Buy Concrete Stains – Your Ultimate Guide

- Enhance Your Space: The Ultimate Guide to the Best Concrete Stains for Indoors and Outdoors